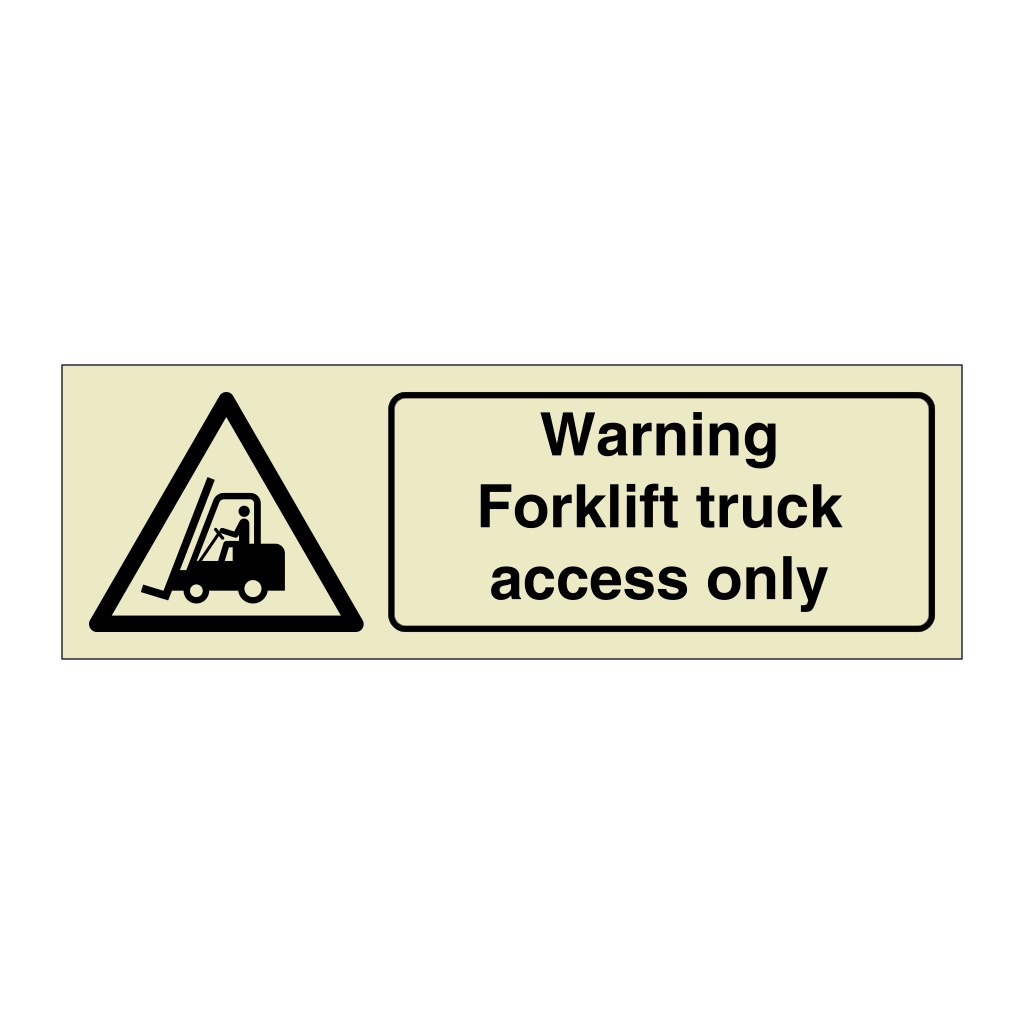

Forklift Truck Safety Signs-- Vital Aesthetic Cautions for Office Safety

Wiki Article

Forklift Safety Signs: Essential Tips for Ideal Placement and Exposure

Making certain the optimal placement and exposure of forklift safety and security indicators is pivotal in maintaining a safe and secure commercial environment. Placing these indications at tactical areas such as entry and leave factors of loading docks, vital facility crossways, and high-traffic storage areas can considerably reduce mishap dangers. Installing signs at eye degree and angling them towards oncoming traffic improves their efficiency. Additionally, using durable materials and high-contrast styles makes certain durability and clearness. However, understanding the nuances of regular examinations and upkeep is just as vital to copyright their functionality-- what important actions should be required to maintain these essential security devices?Key Locations for Safety And Security Indicators

Proper placement of forklift safety indications is essential for keeping a safe working environment. Furthermore, placing indicators near high-traffic storage space locations and blind places can further enhance presence and recognition.Loading docks are specifically unsafe zones where forklift operations are extensive. Signs showing rate restrictions, stop points, and caution zones must be plainly displayed. Junctions within the center are one more critical location where accidents can take place; consequently, stop indications and right-of-way indicators are vital. In pedestrian-heavy areas, signs must alert both drivers and pedestrians to the existence of forklifts, making sure every person continues to be watchful.

Areas with high storage space racks and unseen areas present distinct difficulties. forklift safety signs. Signs in these areas need to warn operators of limited presence and encourage the usage of spotters or added precaution. By focusing on these essential places, organizations can produce a safer, a lot more efficient workplace for all

Height and Angle Considerations

When mounting forklift security indications, taking into consideration the elevation and angle of positioning is vital to guarantee optimum exposure and efficiency. Proper height guarantees that operators and pedestrians can easily see the indicators without obstruction. Usually, safety indicators must be installed at eye level, which is around 4 to 6 feet from the ground. This positioning permits individuals to rapidly discover and check out the signs as they navigate the area.The angle of the indicator is similarly essential. Indications need to be tilted towards the line of view of coming close to traffic or personnel. For example, if a sign is indicated to caution forklift operators, it should be placed directly in their field of view, preferably vertical to their instructions of traveling. In locations with numerous seeing angles, take into consideration using double-sided signs or tilted brackets to keep visibility from different directions.

In addition, ensuring that the indications are not obstructed by other items, equipment, or shelving devices is important. Clear sightlines help stop crashes and boost general safety and security. By thoughtfully taking into consideration height and angle, you can considerably improve the performance of forklift security indicators, thus cultivating a much safer workplace.

Signage Product and Sturdiness

Choosing the proper product for forklift safety signs is important for guaranteeing their long life and effectiveness. In environments where forklifts run, indicators are commonly revealed to continue reading this extreme problems, including physical effects, chemical spills, and differing temperatures. Selecting resilient materials like aluminum, high-density polyethylene (HDPE), and polyvinyl chloride (PVC) can dramatically boost the indications' lifespan.Aluminum is a preferred option due to its resistance to corrosion and rust, making it optimal for both interior and outside settings. In addition, its lightweight nature helps article with easy installment and repositioning. HDPE is an additional durable choice, known for its superb resistance to chemicals and influence. It is specifically ideal for settings where chemical direct exposure prevails. PVC, on the other hand, offers an excellent balance in between toughness and cost-effectiveness, making it a common choice for several industrial atmospheres.

Moreover, the printing method made use of on these materials likewise contributes in longevity. UV-resistant inks and protective laminates aid in stopping fading and damage from sunshine and various other ecological elements. Sticking to these considerations makes sure that forklift safety indications continue to be visible and understandable over extended periods, therefore keeping a secure functioning environment.

Making Sure Indicator Visibility

While picking durable materials for forklift security indicators is essential, guaranteeing their presence is equally important for preserving a secure setting. Reliable visibility can be accomplished with strategic positioning, appropriate lighting, and using high-contrast colors. Indications must be placed at eye level and in locations where drivers and pedestrians are most likely to see them, such as at entry factors, intersections, and areas with high traffic.Correct lights is critical to make certain that indicators are noticeable in all problems. Setting up sufficient lighting in poorly lit locations or utilizing reflective products on indications can considerably enhance presence.

In addition, staying clear of aesthetic clutter around the signs is necessary. A lot of check in one area can overwhelm and perplex people, lowering the efficiency of each sign. Clear, succinct messaging and making sure signs are free from blockages such as equipment or storage space products will certainly further boost their exposure and effectiveness, adding to a much safer office setting.

Routine Inspection and Upkeep

Consistency is vital to maintaining the performance of forklift safety indicators, making regular examination and maintenance essential. To guarantee these signs proceed to communicate critical info clearly, they need to be routinely looked for wear and tear, fading, or obstruction. forklift safety signs. Gradually, exposure to the components and functional tasks can degrade their exposure and readability, undermining their functionThroughout inspections, examine each indicator's condition, guaranteeing message and symbols remain clear and dynamic. Any type of indications revealing indicators look at this website of damage or fading must be immediately replaced.

Verdict

Appropriate positioning and exposure of forklift safety indicators are vital in reducing office mishaps. Positioning signs at vital locations such as access and departure factors, facility junctions, and high-traffic storage areas, while ensuring they are installed at eye degree and angled in the direction of oncoming traffic, improves their effectiveness. Making use of resilient products like light weight aluminum and HDPE, together with high-contrast shades and strong fonts, additionally improves exposure. Regular inspections and maintenance are necessary to maintain indication performance and advertise a safer working environment.Report this wiki page